Solid Works

Solid Works is a solid modelling computer-aided design (CAD) and computer-aided

engineering (CAE) application published by Dassault Systems . the goal of building 3D

CAD software that was easy-to-use, affordable, and available on the Windows desktop.

Operating later from Concord, Massachusetts, Solid Works released its first

product Solid Works 95, in November 1995. [5][6] In 1997 Dassault. Solid Works is a solid

modeller, and utilizes a parametric feature-based approach which was initially developed

by PTC (Cero/Pro-Engineer) to create models and assemblies. The software uses the Para

solid modelling kernel. Solid Works Corporation was founded in December 1993 by

Massachusetts Institute of Technology graduate Jon Hirsch tick. Hirsch tick used $1 million

he had made while a member of the MIT Blackjack Team to set up the company. Initially

based in Waltham, Massachusetts USA, Hirsch tick recruited a team of engineers with the

goal of building 3D CAD software that was easy-to-use, affordable, and available on the

Windows desktop. Operating later from Concord, Topics include

Introduction to PDC & CAD/CAM/CAE

SOLIDWORKS is powerful 3D CADD software that helps in shortening the design cycle and

increases productivity. SOLIDWORKS is the world’s leading product design software that

facilitates us to deliver innovative solutions to the engineering or technical industries

MANJU CAD EXPERTS offers the best classroom training in India that helps the learner to

get in-depth knowledge of various tools and features available in the Solid works software.

Being a 2D and 3D parametric modeller, SOLIDWORKS is essential to most engineering

and drafting systems MANJU CAD EXPERTS provides software training on a wide range

of courses in the field of CAD, CAM & CAE and also they put great emphasis on delivering

quality training to students. Further, while taking the coaching classes for SOLIDWORKS,

students are encouraged to do Internship and also gets an option to go for industrial visits.

Further while taking the SOLIDWORKS training, students get many benefits like student

panel, study materials, e-books, tutorials, and projects which gives them a better

understanding of the concepts of software and also helps them to grow in their career. CAD

CAM EXPERTS. After the course completion, the student receives a SOLIDWORKS

certificate and also gets placement assistance .

Course modules

Introduction

Sketch Module

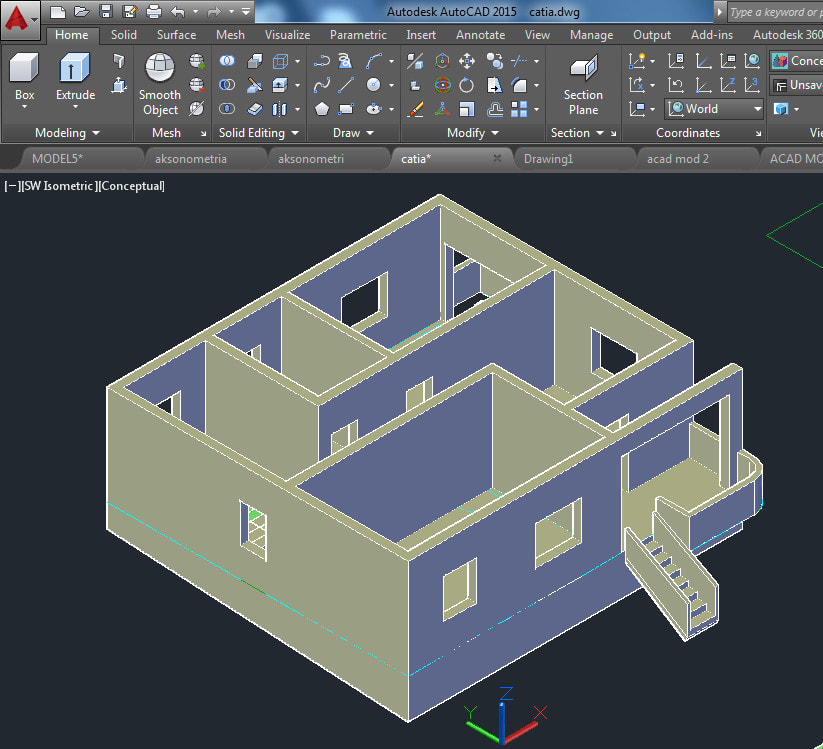

Solid Modelling

Sheet Metal Design

Surface Modelling

Weldment Design

Assembly Module

Drafting Module

Course Contents

Syllabus

Parametric and Non-parametric Modelling

Introduction to Solid works

GUI of Solid works

Sketch Entities

Sketch Modifying Tools

Parametric Modelling

Geometric Relations

Fully Defined Sketch

Over defined Sketch

Under defined Sketch

Creating Base Features

Creating Reference Geometries

Creating New Planes

Creating Reference Axes

Creating Reference Points

Creating Reference Coordinate Systems

Creating Cut Features

Creating Standard Holes Using the Hole Wizard

Adding External Cosmetic Threads

Selection Methods

Changing the Sketch Plane of the Sketches

Editing Using the Instant3D Tool

Deleting Features

Deleting Bodies

Suppressing Features

Unsurprising the Suppressed Features

Creating various types of Curves

Creating Dome Features

Creating Indents

Creating Deform Features

Creating Flex Features

Creating the Mounting Boss

Creating Snap Hooks

Creating Snap Hook Grooves

Creating Vents

Creating a Lip/Groove Feature

Creating Freeform Features

Editing Appearance

Editing Scene

Editing Decal

Rendering Settings

Rendering a Region

Final Renderin

Creating the Base Flange

Creating the Edge Flange

Creating the Sketched Bend

Creating the Miter Flange

Creating Closed Corners

Creating Hems

Creating the Jog Bend

Breaking the Corners

Creating Lofted Bends

Converting a Solid Body into a Sheet Metal Part

Ripping the Edges

Forming Tool design

Creating an Extruded Surface

Creating a Revolved Surface

Creating a Swept Surface

Creating a Lofted Surface

Creating a Boundary Surface

Creating a Planar Surface

Creating a Fill Surface

Creating a Radiated Surface

Offsetting Surfaces

Trimming Surfaces

Untrimming Surfaces

Extending Surfaces

Knitting Surfaces

Filleting Surfaces

Replacing Faces

Deleting Faces

Mirroring Surface Bodies

Adding Thickness to Surface Bodies

Creating a Thicken Surface Cut

Creating a Surface Cut

3D Sketching

Assign Structural Members

Performing end operations

Using End Cap, Gusset

Introduction to Assembly

Assembly Approaches

Applying Standard Mate

Applying Advanced Mate

Applying Mechanical Mates

Creating Patterns of Components in an Assembly

Copying and Mirroring Components

Smart Fasteners

Hiding Components

Creating the Exploded State of an Assembly

Creating Exploding and Assembly Videos

Design Library and Toolbox

Motion Study

Adding New Sheets to the Drawing Views

Editing the Sheet Format

Creating User-Defined Sheet Formats

View Layout Tab

Creating different views from the 3D Model

Generating Drawing Views of the Exploded State of an Assembly

Editing and Modifying Drawing Views

Adding Balloons to the Drawing Views

Adding Annotations to Drawing Views

Adding the Bill of Materials (BOM) to a Drawing

Benefits

1) Another advantage of using the simulation software is that it is simple to learn how

to use it and creating 3D designs are easier which improves productivity. With the

simulation tool it is no longer necessary for the designer to remember complex mathematical

rules. This software does the work while the designer focuses on creating exceptional

product designs and testing them.

2) The software give the designer the ability to import data and translate it, store it

securely, and maintain its flexibility and accessibility. Also, simulation makes it possible

to test designs in real time and under a number of different circumstances. Simulation makes

the design process easier while increasing the quality and productivity of the design, while

reducing cost and the time it takes to get the product to the market.

3) Engineers and designers see this software as an innovative way to solve project

challenges. This capable 3D software improves the communication and teamwork among

project members, and makes data more easily accessible. Clients, designers, vendors,

engineers, and manufacturers are able to work together more efficiently while they share 2D

drawings and 3D models with one another.

4) This capability produces improved designs, increases the efficiency of the

production, and decreases inaccuracies. The software makes it possible for everyone

involved with a project to work as a team effectively using one platform. The enhancement

of the collaboration tools and the use of only one platform, simplifies the creation of

products and reduces errors since it is not necessary to open multiple applications during the

entire design process.

5) With these abilities, the customer is kept satisfied and increases the likelihood of

return business. Available from a number of providers, SOLIDWORKS 3D can also be

obtained by internet download. The principal reseller of the program software, CATIA, has

become very well respected for its ability to identify and match the correct software to the

specific needs of varying businesses

Consulting Agency for Your Business

Rapidiously engage fully tested e-commerce with progressive architectures.